Advanced Biofilters for Efficient Exhaust Air Treatment and Emissions Reduction

Biofilters for Exhaust Air Treatment: Sustainable, Efficient Purification

Biofilters for exhaust air treatment are advanced biological systems designed to effectively purify polluted exhaust air by removing volatile organic compounds (VOCs) and unpleasant odors. They consist of an organic carrier material that supports beneficial microorganisms. These microorganisms break down VOCs and odors naturally into harmless components, making biofiltration a sustainable and highly effective air purification solution.

PureAir BioTech’s advanced biofilters offer significant advantages over conventional systems: with a proprietary layered design that enhances VOC reduction, odor neutralization, and CO₂ footprint reduction, our biofilters set new standards in exhaust air treatment. Unlike traditional solutions, PureAir BioTech biofilters ensure even moisture distribution, preventing clogging, and requiring minimal maintenance—achieving cleaning efficiencies of up to 99%.

This efficient, cost-effective, and environmentally friendly approach provides businesses with a reliable solution to reduce their environmental impact while meeting stringent air quality regulations. PureAir BioTech’s biofilters strike the optimal balance between high-performance air purification and sustainable, low-maintenance operation.

Beyond Traditional Filters:

Discover PureAir’s Unique Biofiltration System

Our Advanced Biofilter System: Single-Layer and Double-Layer Options for Optimal Exhaust Air Treatment

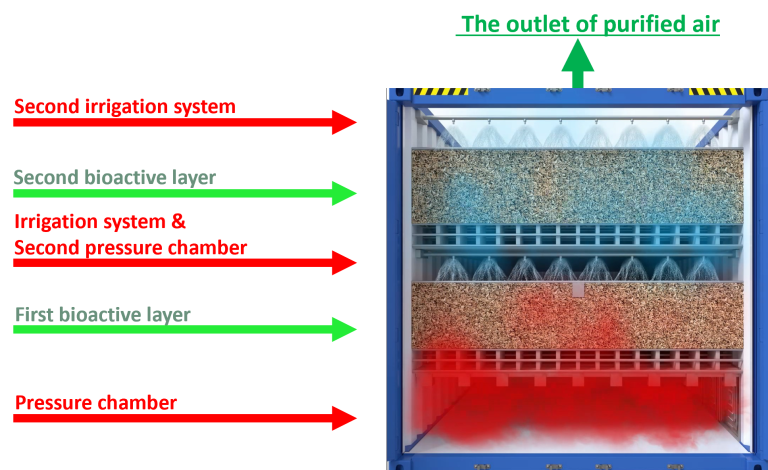

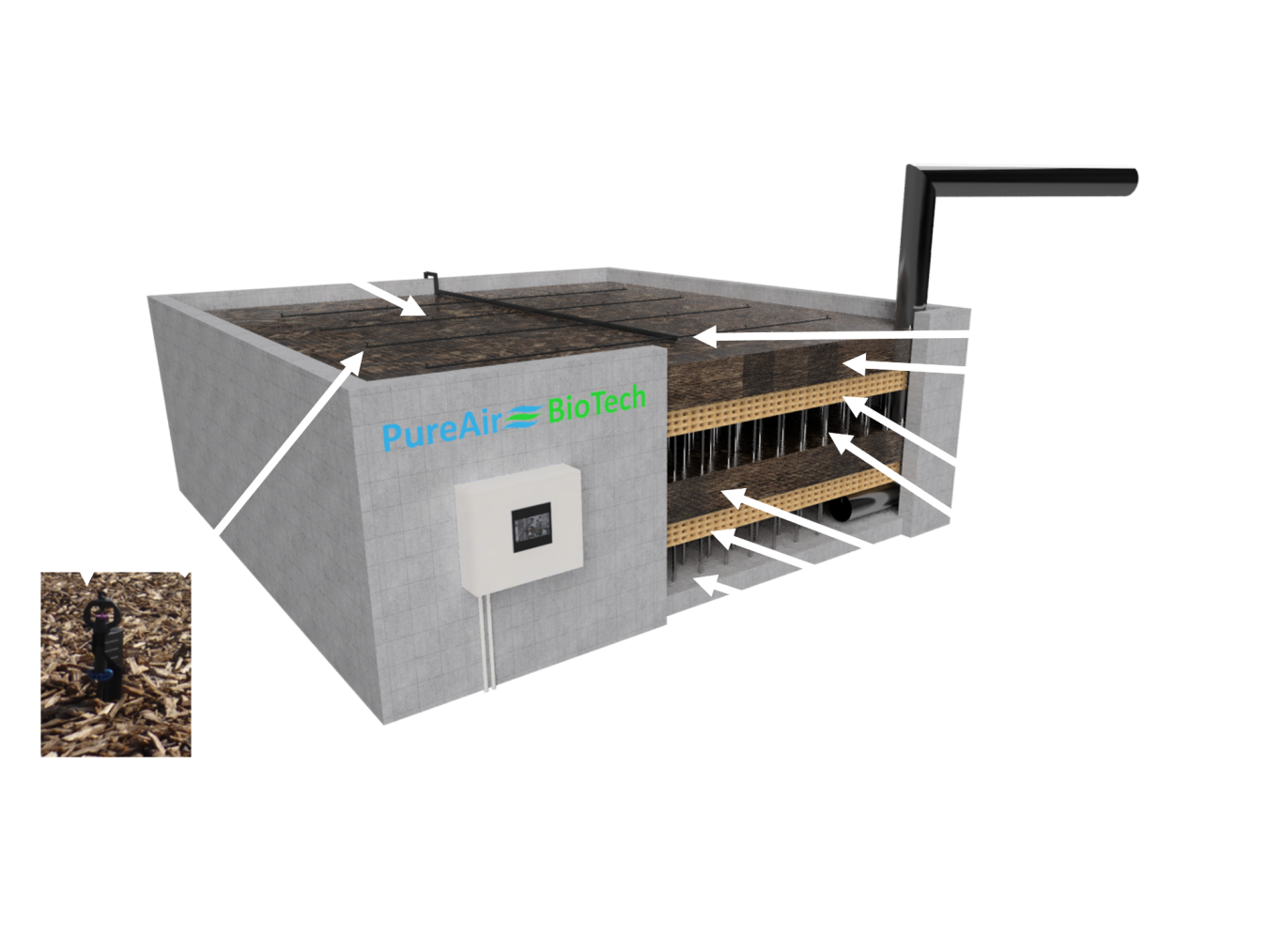

Our biofilter system is available in both single-layer and double-layer versions, each designed to deliver efficient exhaust air treatment. The key difference between the two lies in the double-layer option, which includes an additional independent filter system positioned above the first bioactive layer. Each filter layer is individually monitored and controlled, ensuring optimal performance at all times. If needed, each layer can be re-impregnated with special bacteria through the integrated irrigation system.

Our proprietary control system allows for comprehensive monitoring of essential data, such as pressure, current and target humidity, temperature, and water consumption. These parameters are automatically regulated based on predefined settings, ensuring optimal conditions for air purification.

Depending on your needs, we offer the filters in various configurations, including containers, surface filters, or customized models with roofs and chimneys—ideal for a wide range of exhaust air treatment applications. The flexibility of our system means there are virtually no limits to filter placement, from ground level to rooftop installations or even covered parking areas.

Scroll down to learn more about the power of our advanced irrigation technology!

Optimized Moisture Control and Irrigation System for Efficient Exhaust Air Treatment

Structural Setup

The following sectors are among our customers:

- Sludge drying

- Wastewater treatment plants

- Waste treatment facilities

- Automotive suppliers

- Automotive manufacturers

- Wood processing industry

- Food processing industry

- Agricultural enterprises

- Manufacturing industrial sector

-

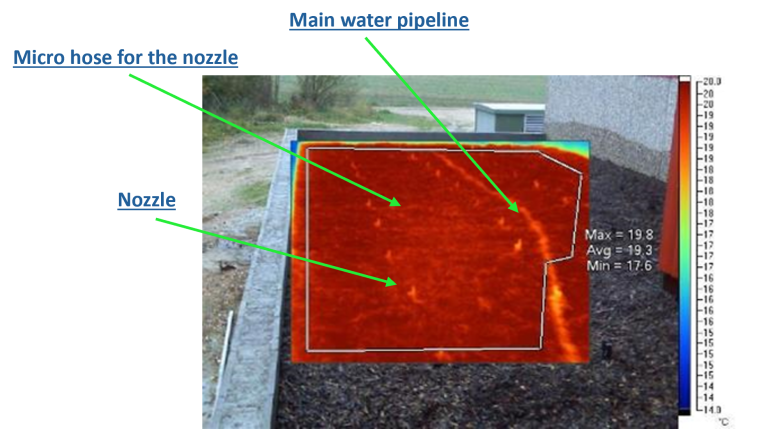

The moisture in the biofilter is continuously monitored and controlled in each bioactive layer, ensuring efficient exhaust air treatment. If the predefined parameters in a bioactive layer are exceeded, the control system automatically signals the corresponding solenoid valve to open. The irrigation system then moisturizes the bioactive layer until the parameters are slightly exceeded again, ensuring the Hartmann Biofilter maintains the optimal moisture level. As a result, a previously installed exhaust gas washer is no longer needed for effective air purification.

The irrigation system consists of numerous small nozzles embedded in the bioactive layer and supplied with water through microtubes. Both the nozzles and microtubes are placed within the bioactive layer, allowing the irrigation system to function even at low temperatures. This ensures continuous, reliable exhaust air treatment, eliminating the need for shutdowns and supporting consistent, high-performance filtration.

Controlling System

Our state-of-the-art control system is based on reliable Siemens PLC technology, ensuring maximum precision and efficiency. Relevant operational data is recorded every second, including:

•Moisture content of each bioactive layer

•Pressure in the pressure chambers

•Temperature

•Water consumption

•Wastewater volume

•Time and date

For seamless integration into your operations, we offer the option to link our control system with your operational management system – either via data cable or wirelessly.

Additionally, we offer the option to have the Biofilter monitored by our experienced technical team. This allows us to make adjustments as needed to ensure optimal performance.

An real-time monitoring of raw and clean gas values is also available as an option, ensuring continuous tracking and documentation of cleaning performance.

With our control system, you have complete oversight of all relevant operational data – for maximum efficiency and full control of your exhaust air treatment system.

Copyright @ 2024 PureAir BioTech Inc. All Rights Reserved. Privacy Policy Developed by Privacy Policy Generator

Highest Filtration Performance for Clean Air with Biological Exhaust Air Treatment Systems for Industrial Applications

Wir benötigen Ihre Zustimmung zum Laden der Übersetzungen

Wir nutzen einen Drittanbieter-Service, um den Inhalt der Website zu übersetzen, der möglicherweise Daten über Ihre Aktivitäten sammelt. Bitte überprüfen Sie die Details in der Datenschutzerklärung und akzeptieren Sie den Dienst, um die Übersetzungen zu sehen.